Introduction to variable pressure control technology

Description of variable pressure control technology

부스터 펌프 시스템의 토출압 제어 기준이 유량에 따라 달라지는 가변압(배관

마찰손실양정)을 따르도록 제어하는 것.

New technology

-

Implementing variable pressure control considering the friction

loss lift of piping for the first time in Korea/world

-

Automatically calculating the flow rate in the current operating

state (within ±3%)

- New product certification (NEP: NEP-MOTIE-2020-095)

Convenience

-

Automatically calculates the friction loss lift of piping based on

building information

(number of blocks, number of floors, number of households, etc.)

-

Automatic setting of the starting pressure according to the

maximum pressure

-

Converts the friction loss head of the pipe into a pressure

equation for flow and automatically sets it as a variable pressure

reference line

-

Provides information on current flow, accumulated flow, current

power and accumulated power

-

Provides operation information (number of revolutions, operating

hours, etc.) for each pump

-

Preventing hunting and lowering of pressure when switching the

pump, through the implementation of the optimal pump replacement

method

Effect

-

[Power Savings] Power by flow rate is reduced by about 20%

compared to existing products depending on the flow rate

-

[Energy Savings] Power consumption for 24 hours is reduced by

about 20% compared to existing products depending on the place of

use

Change in control method

| Generation |

1st |

2nd |

3rd |

4th (current) |

Control

method |

ON/OFF |

Constant pressure control |

Constant pressure control |

Variable pressure control |

Water supply

method |

고가수조방식 |

급수펌프직송방식 |

급수펌프직송방식 |

급수펌프직송방식 |

| Composition |

|

|

|

|

| Generation |

3rd |

4th (current) |

Control

method |

Constant pressure control |

Variable pressure control |

Water supply

method |

급수펌프직송방식 |

급수펌프직송방식 |

| Composition |

|

|

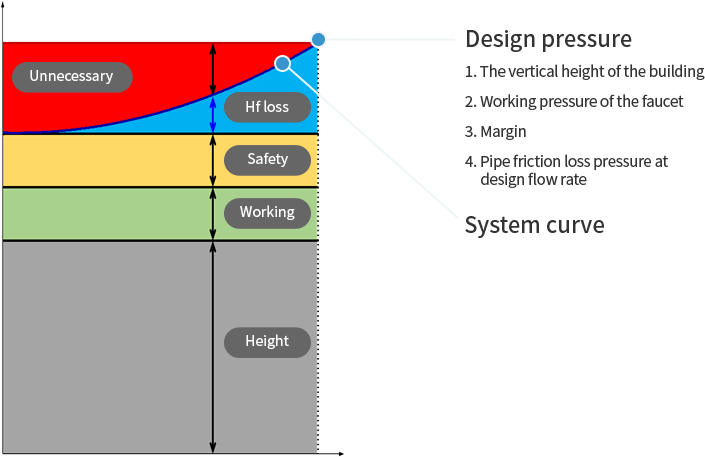

How to decide the flow rate (flux) and pressure

| Flux |

Lift |

1. Calculation method by exponential load unit (FU)

2. Calculation method based on the number of instruments and the

rate of simultaneous use

3. Calculation method for water supply in apartment houses

|

1. Vertical height from the water tank to the farthest faucet in

the process of transferring water

2. The total lift is the sum of the actual vertical height and the

loss due to the pipe material, length and diameter of the pipe

converted into vertical height. It is determined by the pressure

generated from the discharge part of the pump.

|

| Lift |

1. Vertical height from the water tank to the farthest faucet in

the process of transferring water

2. The total lift is the sum of the actual vertical height and the

loss due to the pipe material, length and diameter of the pipe

converted into vertical height. It is determined by the pressure

generated from the discharge part of the pump.

|

| Design pressure |

Constant pressure control regardless of

flow rate change as a design pressure

|

| System curve |

A curve that considers pipe friction loss

due to flow, and it is controlled along with this curve

|

| Generation |

Control method |

Control standards |

Control factors |

| 3rd |

Constant pressure control |

Design pressure |

Pressure information |

| 4th (current) |

Variable pressure control |

System curve |

Flow rate information

Pressure information

|

| Control standards |

Control factors |

| Design pressure |

Pressure information |

| System curve |

Flow rate information

Pressure information

|

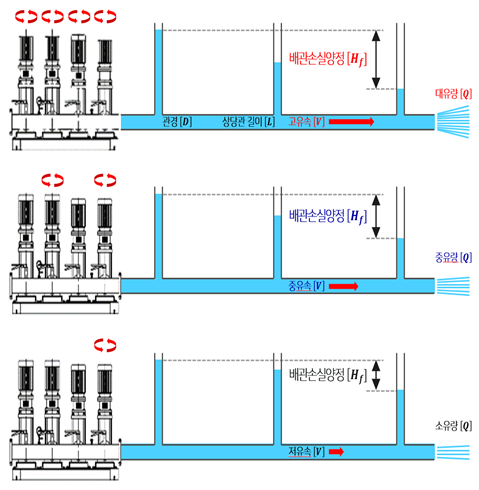

배관 마찰 손실

| 배관 마찰 손실 |

When the flow passes through the pipe, the pressure is lost

due to friction between

the fluid and the pipe. The more fluid that passes, the

greater the pressure lost.

|

| 배관 마찰 손실 Essential elements for the calculation |

1. The diameter of the pipe

2. Cross-sectional area of pipe

3. Amount of fluid passing through

4. Fluid velocity

5. Reynolds number

6. Friction loss coefficient

|

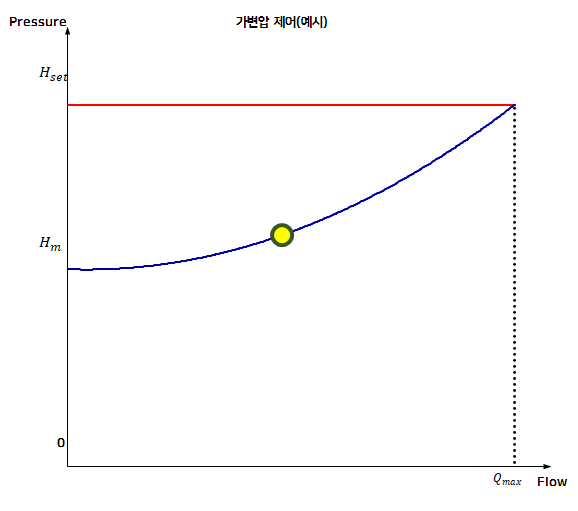

배관 마찰 손실

Control

standards

|

System curve |

Automatic setting technology |

Control

factors

|

Pressure information,

Flow information

|

Pressure sensor,

Flow rate calculation technology

|

| Benefits |

1. Provides flow information

2. Extends life span of pump and pipe

3. Saves power by more than 20% compared to scheduled

pressure control

|

Variable pressure control

|

Variable pressure baseline automatic setting technology

|

Variable pressure

baseline automatic setting technology

|

1. Enter basic information |

- Enter the number of building blocks, floors, households, area,

maximum flow rate

- Using the Darcy Weisbach/Harzen Williams formula based on the

input value

|

| 2. Enter directly |

- 최고압력(설계압력)과 배관마찰손실양정을 뺀 시작압력을 직접 입력

|

| 3. Set variable pressure baseline |

- Formulate and establish a variable pressure baseline for total

flow

|

| Flow calculation technology |

|

Flow calculation technology

|

1. Performance test |

- Measure all performance of the booster pump system within the

measurable range for the flow rate

|

| 2. Formulation for flow |

- After defining all data with a mathematical formula, load it

into the device

|

| 3. Flow calculation |

- Acquire operation data in real time, substitute it into the

formula, and inversely calculate the flow rate

|

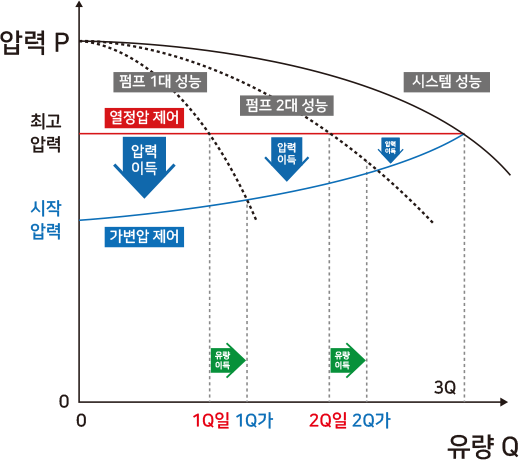

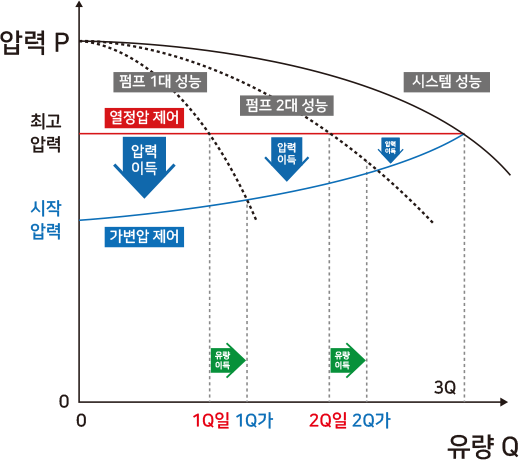

Gain by variable pressure control

-

[Pressure Gain] It refers to the benefit of eliminating

unnecessary pressure. The smaller the flow rate being used,

the greater it will be.

-

[Flow Gain] This is a gain generated by increasing the range of

the flow rate that can be supplied before the maximum interlocking

of the pump. There will be a section in which processing can be

performed even when only one unit is driven, where two units must

be operated if under constant pressure control.

-

[Power savings] You can save power through pressure gain and flow

gain.

Power Savings Effect

Total

power

|

Pump

configuration

|

Flow

[$m^3/min$]

|

Power[kW] |

Reduction rate

[%] |

Reduction rate

[%] |

| Variable pressure control |

Constant pressure control |

6

kW |

대소

용량

|

0.04

~

0.2

|

0.95

~

4.86

|

1.66

~

5.43

|

20.9 |

21.0 |

동일

용량

|

1.06

~

4.58

|

1.86

~

5.46

|

27.5 |

33

kW |

대소

용량

|

0.15

~

0.1

|

3.10

~

24.52

|

3.76

~

28.52

|

22.1 |

동일

용량

|

3.21

~

26.70

|

4.95

~

31.32

|

23.3 |

88

kW |

대소

용량 |

0.4

3.04 |

8.87

~

72.80

|

10.99

~

76.45

|

15.3 |

동일

용량

|

12.21

~

77.45

|

14.90

~

77.42 |

16.9 |

| Field test |

| Number of households |

540 households |

Number of floors |

20 Floors (1 floor in Basement) |

| Power |

37 kW |

Number of floors using power |

B1 ~ 7 above ground level |

Test

results

(30days)

|

Classification |

Variable pressure control |

Constant pressure control |

Reduction rate [%] |

| Total flow amount |

1,806 |

1,813 |

- |

| Integrated electricity amount of electricity |

1,039 |

1,316 |

21.1 |